Processing Technology

01

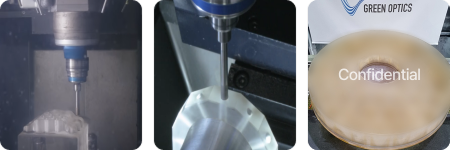

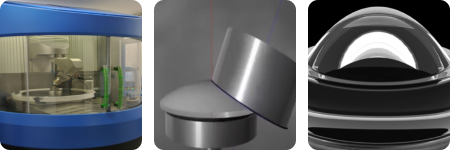

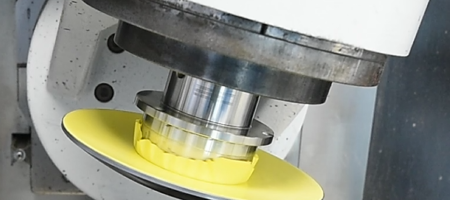

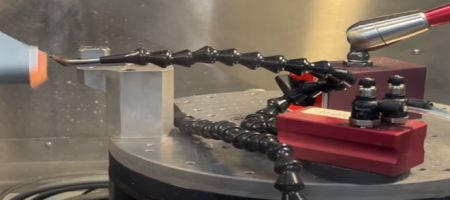

Possesses 5-axis to 7-axis ultra-precision machining equipment and specialized operators, securing spherical and aspherical machining technology with precision within 2 μm.

- Lightweight machining

-

Variation per hole within 100 μm,

achieving up to 82.5% weight reduction.

- Gyro block machining

- Parallelism within 158 nm, eccentricity with respect to the channel intersection within ± 0.03 mm tolerance, and squareness within 5″.

- Aspherical machining

- Tolerance: RMS ≤ 0.1 μm.

02

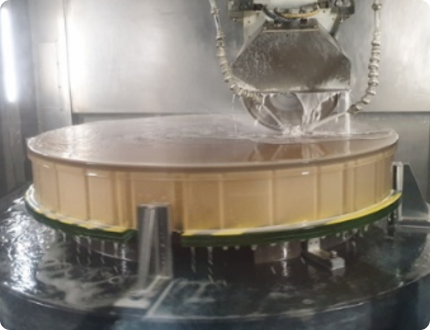

1600 mm-class processing technology, lightweight, and dome manufacturing technology

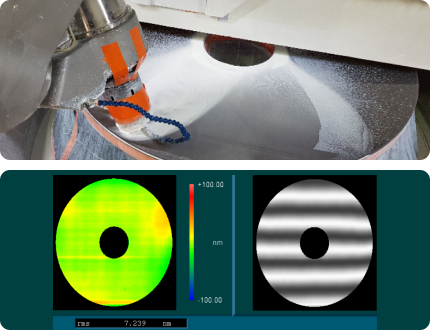

- Possessing polishing technology that developed large off-axis aspherical surfaces and introduced them to mass production

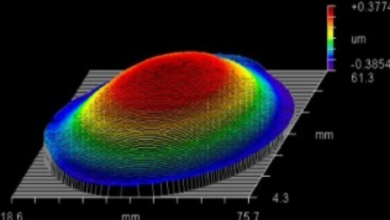

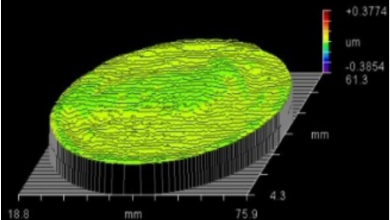

- The data below secured production of 302 mm-class products to rms 4.376 nm and possesses technology capable of polishing products up to 1600 mm

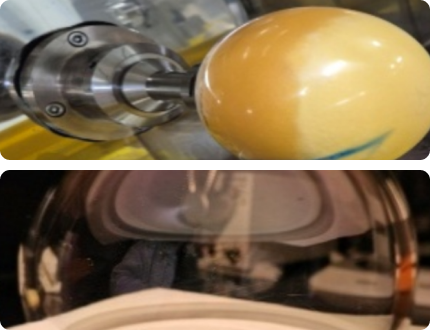

- Hyper-hemispherical dome manufacturing technology is the only successful development in Korea

- 01. Primary Mirror, Zerodur

-

- Aperture Ø 1600 mm(Concave Parabolic)

- Surface Errors RMS < 7.5 nm

- Coating Protected Silver, %R > 98%

- Waveband Visible & MWIR

- 02. Concave Aspherical Mirror, Zerodur

-

- Aperture Ø 1200 mm (Convex Aspheric, Lightweight)

- Surface Errors PV < 79 nm, RMS < 12 nm

- Coating Protected Silver, %R > 98%

- Waveband Visible

- 03. Hyper-Hemispherical Dome, Sapphire

-

- Aperture Ø 117.2 (Dome)

- Surface Errors PV < 2/Lamda, Ø 50 AnyPoint

- Coating AR Coating, %T > 90%

- Waveband Visible & MWIR

Polishing Technology

01

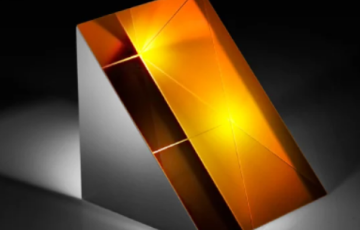

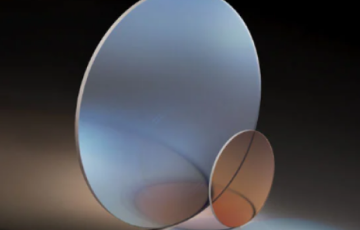

Secured ultra-precision polishing technology with surface roughness levels of 0.2 nm and Rms below 10 nm for various shaped optical products, including lenses, mirrors, windows, and prisms

| spec | Spherical | |||

|---|---|---|---|---|

| Commercical | Precision | Highprecision | ||

| Specification | Tolerance | |||

| Outer diameter | ~ 1,200 mm | ± 0.1 mm | ± 0.02 mm | ± 0.01 mm |

| Curvature | R5 ~ R100 | ± 5 fringe | ± 3 fringe | ± 2 fringe |

| R100 ~ R1200 | ± 10 fringe | ± 5 fringe | ± 2 fringe | |

| Surface quality | S/D | 60/40 or less | 40/20 or less | 10/5 or less |

| rregularity (PV) | Lambda | 1/2 λ | 1/10 λ | 1/20 λ |

| Roughness (RMS) | RMS | 0.8 nm | 0.5 nm | 0.3 nm |

| Eccentricity (angle) | Sec | 60″ or less | 30″ or less | 10″ or less |

| spec | Aspherical | |||

|---|---|---|---|---|

| Commercical | Precision | Highprecision | ||

| Specification | Tolerance | |||

| Outer diameter | ~ 1,200 mm | ± 0.02 mm | ± 0.02 mm | ± 0.02 mm |

| Curvature | R5 ~ R100 | ± 5 fringe | ± 3 fringe | ± 2 fringe |

| R100 ~ R1200 | ± 10 fringe | ± 5f ringe | ± 2f ringe | |

| Surface quality | S/D | 60/40 or less | 40/20 or less | 10/5 or less |

| Irregularity (PV) | Lambda | 1 λ | 1/4 λ | 1/10 λ |

| Roughness (RMS) | RMS | 2 nm | 1 nm | 0.5 nm |

| Eccentricity (angle) | Sec | 60″ or less | 30″ or less | 10″ or less |

| spec | Flat | |||

|---|---|---|---|---|

| Commercical | Precision | Highprecision | ||

| Specification | Tolerance | |||

| Outer diameter | ~ 1,800 mm | ± 0.05 mm | ± 0.05 mm | ± 0.05 mm |

| Curvature | ∞ | - | - | - |

| ∞ | - | - | - | |

| Surface quality | S/D | 60/40 or less | 40/20 or less | 10/5 or less |

| Irregularity (PV) | Lambda | 1/4 λ | 1/10 λ | 1/20 λ |

| Roughness (RMS) | RMS | 0.5 nm | 0.3 nm | 0.2 nm |

| Eccentricity (angle) | Sec | 30″ or less | 10″ or less | 1″ or less |

| spec | Prism | |||

|---|---|---|---|---|

| Commercical | Precision | Highprecision | ||

| Specification | Tolerance | |||

| Outer diameter | ~ 100 mm | ± 0.03 mm | ± 0.03 mm | ± 0.03 mm |

| Curvature | ∞ | - | - | - |

| ∞ | - | - | - | |

| Surface quality | S/D | 60/40 or less | 40/20 or less | 10/5 or less |

| Irregularity (PV) | Lambda | 1/4 λ | 1/10 λ | 1/20 λ |

| Roughness (RMS) | RMS | 0.5 nm | 0.3 nm | 0.2 nm |

| Eccentricity (angle) | Sec | 30″ or less | 10″ or less | 5″ or less |

02

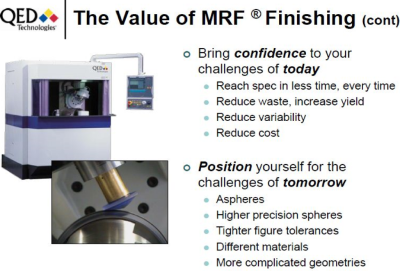

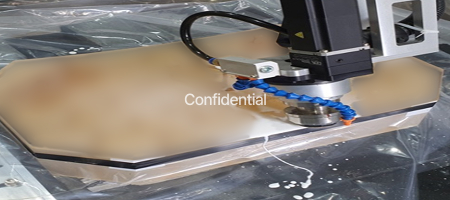

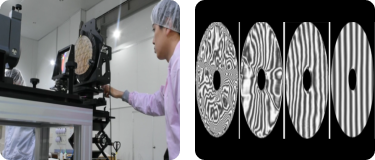

Possessing processing technology capable of producing ultra-precision optical components through CNC-based polishing, measurement, and evaluation

- Material Ge/ZnSe/ZnS/SiC/Si/CaF₂/BaF₂/Al/Cu/Ti

- Shape Spheres/ Aspheric/ Cylinder / Dome / Plate

- Quality up to PV λ/20, Ra < 0.3 nm

- Size Ø 1.2 m

- On-Machine Measurement with CGH Interferometer

~ 7 minutes polishing time