Measurement and Analysis Inspection Technology

01

LIDT (Laser-Induced Damage Threshold)

- Possessing LIDT equipment capable of measuring laser damage threshold

- Maximum energy levels can be used as measurement indicators through LIDT

- Special advantages: Self-developed equipment due to a lack of domestic LIDT evaluation institutions and dependence on overseas, causing delivery delays and a decline in productivity

- Manufactured based on ISO 21254-1,2,3,4 standards

Nd-YAG 1064 nm Laser (Pulse)

| Nd-YAG 1064 nm Laser (Pulse) | |

|---|---|

| Wavelength | 1064/532/355/266 nm |

| Pulse width | 4-7 nm |

| Frequency | 1,10 Hz |

| Beam dia | 7~9 mm |

| Max. LIDT | 1064 nm (300 J/㎠) |

| 532 nm (100 J/㎠) | |

| 355 nm (35 J/㎠) | |

Fiber 1070 nm Laser (CW)

| IPG Laser (CW) | |

|---|---|

| Wavelength | 1070 nm |

| Max. Average Power | 1000 W |

| Output fiber core dia. | 100 um |

| Cooling | Water system |

| Max. LIDT (Power density) |

400 kW/㎠ |

Yb-YAG 343 nm Laser (Pulse)

| Trumpf Laser (Pulse) | |

|---|---|

| Wavelength | 343 nm |

| Average power | 180 W (Max.18 mJ) |

| Pulse duration | 15~20 ns |

| Repetition rate | 10 kHz |

| Pulse diameter | 8 mm |

| Application | LIDT, NLO |

| Max. LIDT (Peak power density) |

500 MW/㎠ |

02

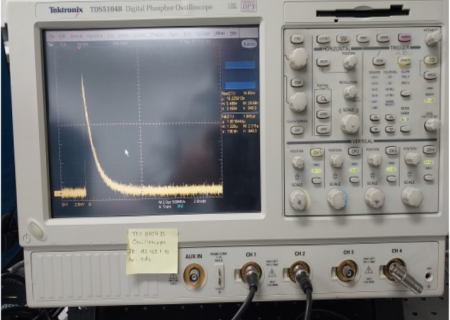

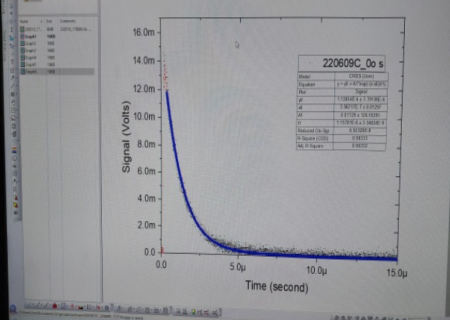

CRDS (Cavity Ring Down Spectroscope)

- Dedicated measurement equipment for high reflectance of 99.85% or higher at 532 nm / 1064 nm

| Reflectance precision | 10-6 order |

|---|---|

| Measurement wavelength | 1064 nm, 532 nm |

| Incident angle(AOI) | 0˚ – 80˚ |

| Measurement sample size | Ø 25 mm , Ø 20 mm |

| High sensitive APD for signal detection | |

| Digitized oscilloscope and Origin software | |

- Averaging irradiation data for 10 minutes for precise measurement (6000 shots)

- Waveplate (λ/2, λ/4): Controllable polarization direction of incident beam to p, s, circle

- Probe beam LD and CCD camera system for precise sample alignment

03

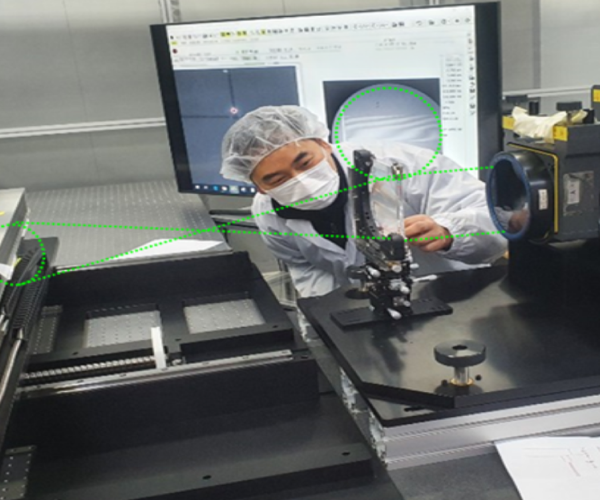

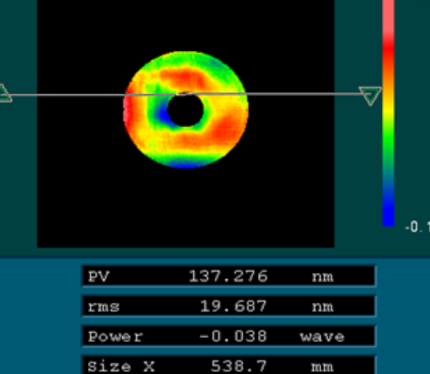

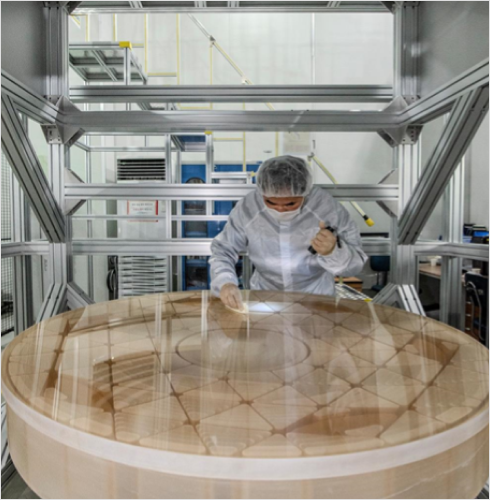

Measurement technology of Large Mirror for Satellite

- Possessing a measurement tower for measuring Ø 1200 mm-class optical systems for satellite observation, large reflectors

- Various items, including lens curvature, surface roughness, and lens center error, can be measured and verified using the measurement tower

- Possessing lens performance evaluation and precision measurement inspection technology, considering atmospheric turbulence and ground vibration for products with curvature of 2000R or higher

Large Reflector Manufacturing and Measurement (rms 20 nm)

04

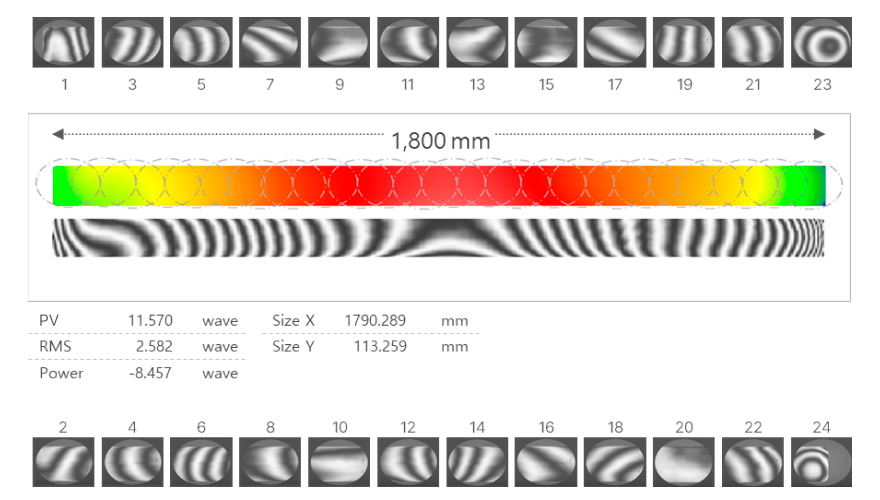

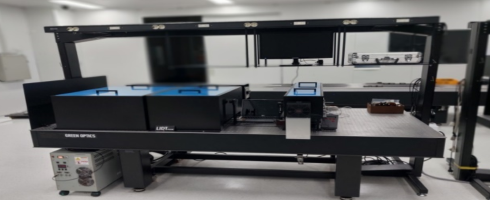

Stitching Technology

- Possessing measurement technology capable of confirming comprehensive data values for long products over 500 mm class in the major axis direction

- Detecting data changes according to wavefront and tilt variations due to environmental factors by position, and providing irregularity data