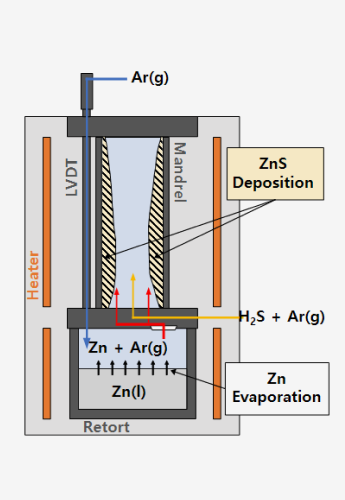

Chemical Vapor Deposition (CVD)

- Zn (g) + H₂S (g) → ZnS (s) + H₂ (g)

-

- Zn (g) Gaseous zinc (Zn(s)→Zn(g) heating)

- H₂S (g) Sulfur source (H₂S(g)→S(g) + H₂(g) heating)

- ZnS (s) Deposited as solid thin film

- H₂ (g) Released as a byproduct

01

Advantages of CVD ZnS

ZnS thin films manufactured through the CVD process possess high transmittance, excellent optical characteristics, and outstanding mechanical strength, making them ideal materials for optical components such as domes or windows of infrared (IR) sensors.

In particular, the CVD method can form uniform and adhesive ZnS thin films even on complex-shaped structures, simultaneously satisfying the precision and durability required for high-performance military optical equipment.

In particular, the CVD method can form uniform and adhesive ZnS thin films even on complex-shaped structures, simultaneously satisfying the precision and durability required for high-performance military optical equipment.

02

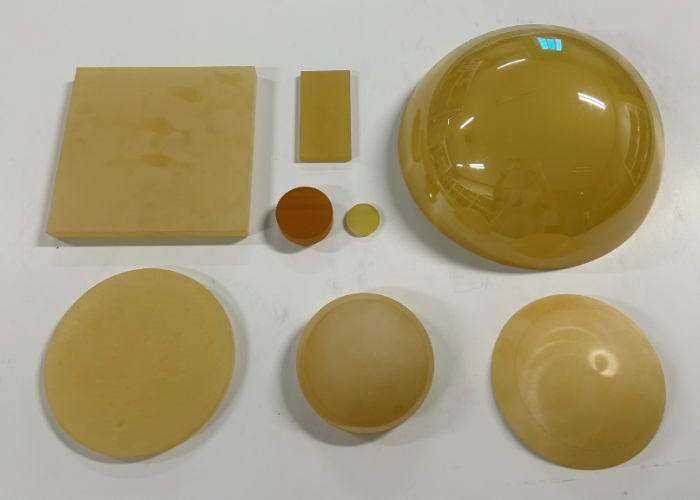

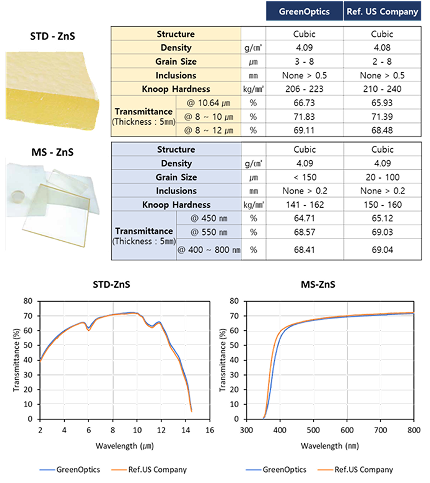

STD-ZnS

- Manufactured using CVD process

- Maximum 70% transmittance in LWIR band (8~12 μm)

- Knoop Hardness of 200 kgf/mm² or higher

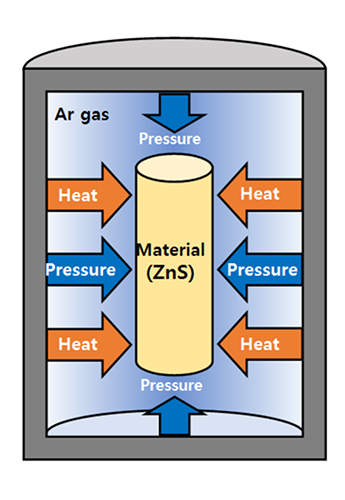

HIP (Hot Isostatic Pressing) Method

This process uses high-temperature, high-pressure isotropic gas to remove pores in ZnS and improve crystallinity, significantly enhancing mechanical strength and optical transparency.

ZnS deposited by CVD is converted through this HIP process into polycrystalline high-transparency multispectral ZnS (MS-ZnS), which provides transmittance characteristics across a wide wavelength range from visible light to infrared regions.

Due to these characteristics, MS-ZnS is highly suitable as a window or dome material for infrared (IR) sensors.

ZnS deposited by CVD is converted through this HIP process into polycrystalline high-transparency multispectral ZnS (MS-ZnS), which provides transmittance characteristics across a wide wavelength range from visible light to infrared regions.

Due to these characteristics, MS-ZnS is highly suitable as a window or dome material for infrared (IR) sensors.

01

Advantages of CVD ZnS

- Improved transmittance using high temperature/high pressure

- Manufacturing MS-ZnS from STD-ZnS

- Enhanced transmittance across wide wavelength bands (visible-far infrared)

02

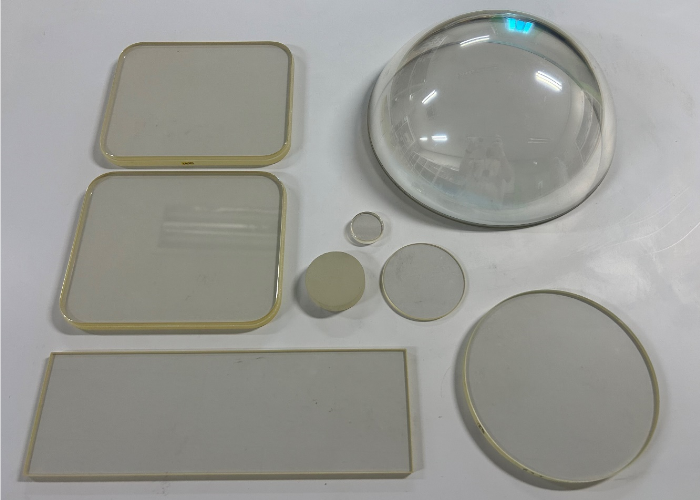

MS (Multispectral)-ZnS

MS-ZnS is a high-performance optical material that simultaneously possesses broad wavelength transmittance and excellent durability.

- Manufactured through HIP treatment process

- 70% transmittance across a wide wavelength band (0.4-12 μm)

- HK 150 Kgf/mm² Knoop Hardness

03

Materials Research Institute

- Leading companies in the ZnS materials field (RAFAEL-Israel, Raytheon-USA, etc.) are advanced enterprises with over 30 years of industry experience in materials.

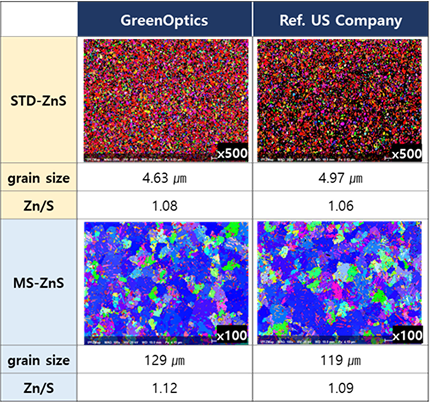

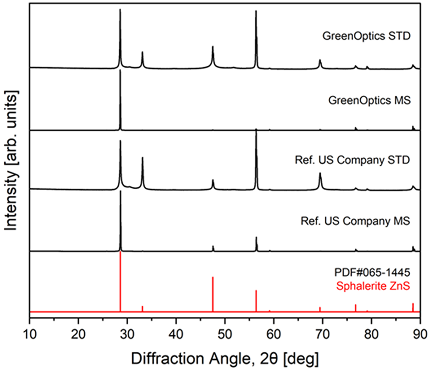

- Green Optics has been developing ZnS materials since 2014 and is producing and delivering materials at levels equal to or superior to those of leading companies.

- Bulk CVD-ZnS material synthesis technology is unique in Korea. Production capacity (current annual level of 5 billion won → annual production capacity of 10 billion won level by the end of 2025)