Coating Technology

01

- Antireflection Coating

-

- Average Reflectance of 0.5% @ 420 nm ~ 680 nm

- AR Coating Reflectance of 0.01% @ 1064 nm, 1550 nm

- AR Coating Reflectance of 0.25% @ 193 nm, 248 nm, 308 nm

02

- Dichroic Mirror

-

- Reflection of 99.96% @ 1064 nm

- Reflection of 99.5% @ 248 nm, 308 nm, 355 nm, 532 nm, 633 nm

03

- Dichroic Filter

-

- Long Pass Filter Type Dichroic Filter

- Short Pass Filter Type Dichroic Filter

- Band Pass Filter Type Dichroic Filter

04

- Band Pass Filter

-

- Narrow Band Pass Filter with a half value of 7 nm (365 nm)

- Visible wide Band pass Filter

- Near infrared wide Band Pass Filter

05

- Infrared Antireflection

-

- Average Reflectance of 0.5% @ 3 um ~ 5 um

- Average Reflectance of 1.0% @ 8 um ~ 12 um

06

- Beam Splitter

-

- Reflects 70% and Transmits 30% ± 3% AOI 45 @ VIS Plate & Qube Types

- Reflects 30% and Transmits 70% ± 3% AOI 45 @ VIS Plate & Qube Types

- Reflects 50% and Transmits 50% ± 3% AOI 45 @ VIS Plate & Qube Types

- Reflects Avg 80% AOI 45 @ 550 ~ 900 nm &Transmits Avg 90% AOI 45 @ 3.6 ~ 4.9 um QubeTypes

07

- ND Filter

-

- Transmittance in the visible light range of 10%, 30%. or 90%

08

- ND Metal Film Coating

-

- Gold Mirrors have 96% @ 500-800 nm Reflectivity

- Silver Mirrors have 98% @ 500-800 nm Reflectivity

- AL Coating. eflectivity of about 85% in visible light and about 90% in infrared regions

01

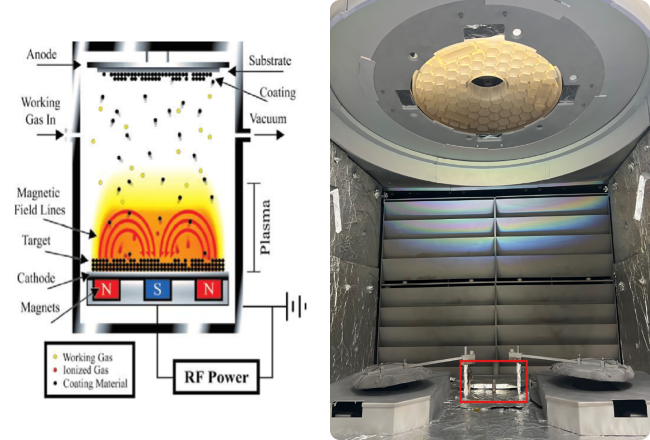

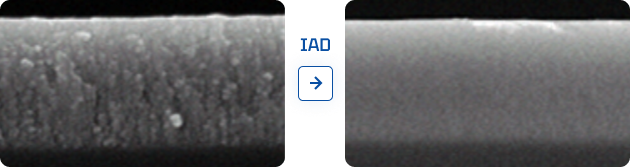

Coating Film Density Enhancement Technology – Establishing coating film enhancement conditions through IAD (RF Source)

- Applied to mirror coating, ELA large optical components, and HIGH POWER laser application product coatings

02

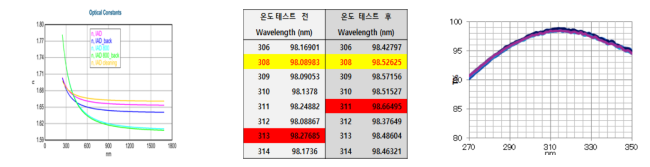

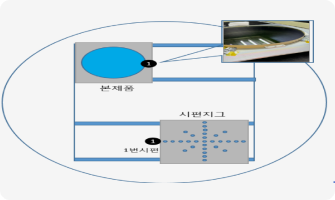

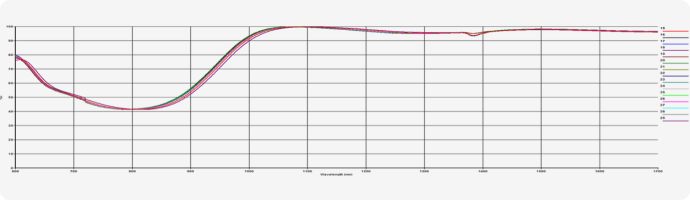

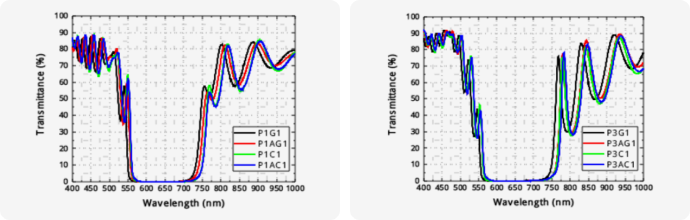

Uniformity Securing Technology - Implementing uniform coating for large products using specimens and masks

Spectral measurement data for symmetry and uniformity of 25 specimens and product positions

- Applied to large window and mirror products over 500 mm

03

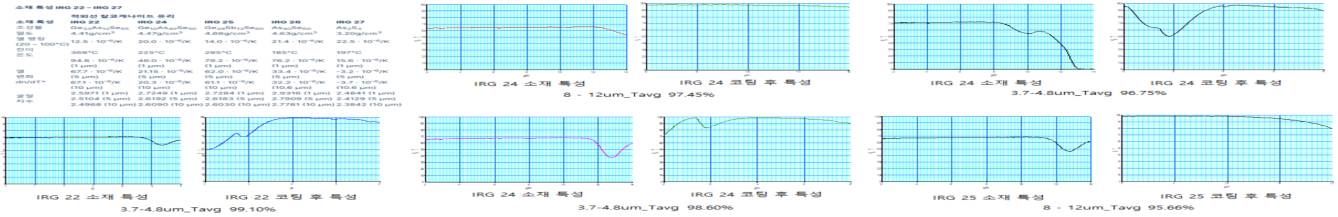

Special Material Coating Technology - Securing IRG (chalcogenide) coating technology that can replace Ge materials

IRG material spectral characteristics and post-coating 3 ~ 5 μm spectral characteristic graphs

- Applied to SWIR, MWIR, and LWIR optical systems as a Ge replacement in IR optical systems

04

Possessing coating technology with low absorption, low scattering within 250 ppm (0.025%), and high reflection (maximum 99.99% or higher) required for ring laser gyroscopes

Ring laser gyroscope transmittance and low scattering measurement values

| Transmittance (S-wave) | Target (ppm) | After Coating (ppm) | After Annealing (ppm) | Result | ||

|---|---|---|---|---|---|---|

| Plane Mirror 1 | 150 ~ 250 | 221 | 172 | 4.50 | ||

| Plane Mirror 2 | 214 | 172 | ||||