Our Infrared (IR) lenses are made from specialized materials, suitable for use across a broad spectrum, including both ultraviolet (UV) and infrared (IR) regions.

Material

- Ge / Silicon / ZnSe / ZnS / MgF2 / CaF2 / BaF2 / Sapphire / Zerodur / Fused Silica

Shape

Bandwidth

Coating

- Anti-Reflection Coating

- Fliter Coating

- DLC Coating etc.

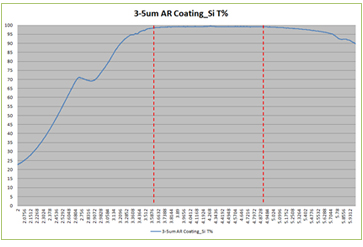

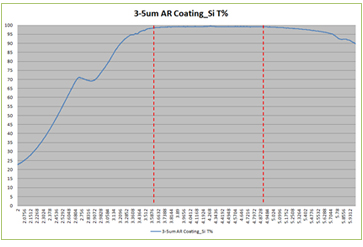

MWIR ANTI-REFLECTION COATING

Procuct of MWIR AR Coating

- In the mid-infrared (3-5um) area AR Coating

| Description |

Specifications |

| Material |

Silicon |

| Form type |

Lens, Window etc. |

| Product size |

Variable |

| Clear Aperture(%) |

>90% |

| Thick Tolerance(mm) |

±0.02mm |

| Surface Accuracy(λ) |

λ/4 @632.8nm |

| Surface Quality(S/D) |

20-10 |

| Angle of Incidence |

0-45˚ |

| Coating |

3.6um~4.9um T avg>98% |

Procuct of MWIR AR Coating

- In the mid-infrared (3-5um) area AR Coating

- Coating for Germanium materials used in infrared optics of thermal imaging optical system

| Description |

Specifications |

| Material |

Germanium |

| Form type |

Lens, Window etc. |

| Product size |

Variable |

| Clear Aperture(%) |

>90% |

| Thick Tolerance(mm) |

±0.02mm |

| Surface Accuracy(λ) |

λ/4 @632.8nm |

| Surface Quality(S/D) |

20-10 |

| Angle of Incidence |

0~45˚ |

| Coating |

3.6um~4.9um T avg>98% |

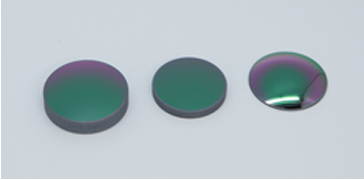

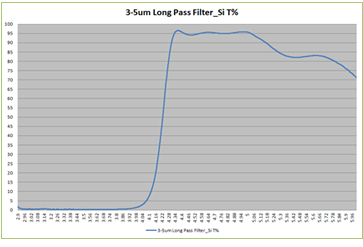

IR LONG PASS FILRER COATING

Procuct of IR Long Pass Filter

- In the mid-infrared (3-5um) area Lonf Pass Filter Coating

- Coating for Silicon materials used in infrared optics of thermal imaging optical system

- In the mid-infrared (3-5um) area AR Coating

| Description |

Specifications |

| Material |

Silicon |

| Form type |

Window Type |

| Clear Aperture(%) |

>90% |

| Thick Tolerance(mm) |

±0.02mm |

| Surface Accuracy(λ) |

λ/4 @632.8nm |

| Surface Quality |

20-10 |

| Angle of Incidence |

0˚ |

| Coating |

3.6um~4.9um T avg<0.5%

4.2~4.9um T avg>95% |

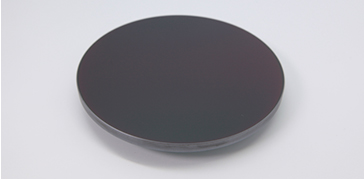

IR LONG PASS FILRER COATING

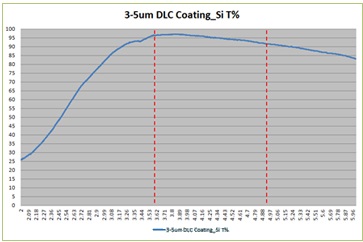

Procuct of IR Long Pass Filter

The use of infrared optical systems often requires the protection of the exposed front surface for the impact to the extreme environment. To this end, we provide a carbon (DLC) coating such as diamond, each of the optical elements. In addition to the anti-reflection effect, the coating is also characterized by external stress, a very high mechanical strength and high elasticity.

Optical components are coated with the silicon and germanium of 3-5㎛ to 8-12㎛ wavelength range.

In addition to the standard coating, we also provide a customized design.

- In the mid-infrared (3-5um) area DLC Coating

| Description |

Specifications |

| Material |

Silicon |

| Form type |

Lens, Window etc. |

| Product size |

Variable |

| Clear Aperture(%) |

>90% |

| Thick Tolerance(mm) |

±0.02mm |

| Surface Accuracy(λ) |

λ/4 @632.8nm |

| Surface Quality |

20-10 |

| Angle of Incidence |

0˚ |

| Coating |

3.6um~4.9um T avg>95% |

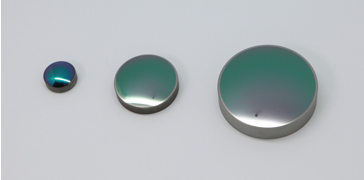

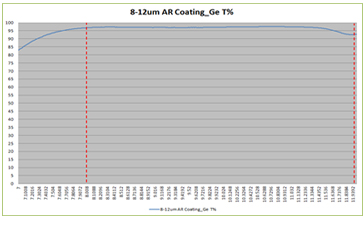

IR ANTI-REFLECTION COATING

AR (Anti-Reflective) coating technology is specifically designed for the far-infrared range (8-12 µm). This coating is applied to germanium materials used in infrared optics, particularly in thermal imaging systems, to enhance transmission and reduce reflections, thereby improving overall optical performance.

Procuct of IR AR Coating

- AR coating technology holds the far-infrared (8-12um) area

- Coating for Germanium materials used in infrared optics of thermal imaging optical system

| Description |

Specifications |

| Material |

Germanium |

| Form type |

Window Type |

| Clear Aperture(%) |

>90% |

| Thickness Tolerance (mm) |

±0.02mm |

| Surface Accuracy(λ) |

λ/4 @632.8nm |

| Surface Quality(S/D) |

<60-40 |

| Angle of Incidence |

0˚ |

| Coating |

8.0um~12.09um T avg>98% |

ALL MENU

ALL MENU